|

By Polly Ouellette

GT College of Engineering

Most of us take for granted the roads and bridges we travel every day. What we don’t know is that almost four in 10 bridges are 50 years or older. Many of the nation’s bridges are approaching the end of their design life, and 614,387 bridges in the U.S. earned a grade of C+ on the American Society for Civil Engineering’s 2017 Infrastructure Report Card.

This is largely due to the country’s rapidly aging infrastructure and the resulting sum of money and labor that is necessary to inspect and maintain these bridges. Ryan Sherman, assistant professor in the School of Civil and Environmental Engineering, wants to help America adapt to the challenges posed by these maturing bridges.

“The interstate era [of the 1950s] is when a lot of these big structures went up,” said Sherman. “I'm talking bridges specifically, but the same can be said about our power plants and buildings. They were designed to last 50 years, but 50 years has come and gone. How do we take some of these existing structures and make sure that we can get more life out of them into the future? How can we extend their service life?”

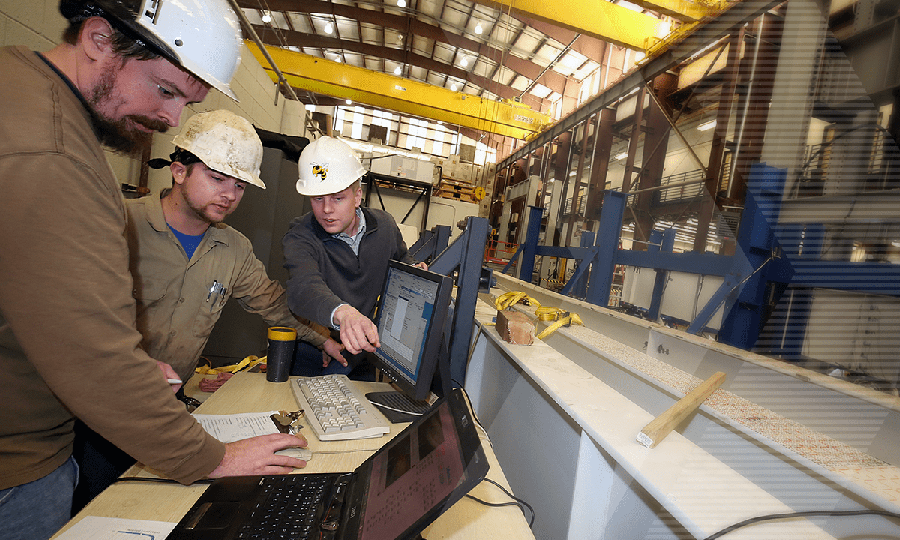

Sherman is working in the Structural Engineering and Materials Lab. His research focuses on the testing of large-scale steel structures and the emerging technologies that we can use to inspect, repair, and build bridges.

One of these technologies is additive manufacturing, more commonly known as 3D-printing. While Sherman says it’s unlikely that we start printing full-length bridges anytime soon, this technique might be used to manufacture small parts or make repairs. It could be a cost-effective way to solve what’s becoming a very expensive problem.

The graduate students working with Sherman regularly use the enormous setup to test steel beams of various lengths, in many conditions, working to develop more accurate models for designing bridges. The team works to establish new design equations and then directly testing them in the lab; this analysis and validation will help engineers design bridges that are cheaper, stronger, and more quickly built.

Structural engineering is an active discipline – from drawing up diagrams, to site visits, to placing instrumentation on bridges, to placing explosives on bridges at the end of their life. Most of all, it’s collaborating with a team of fellow civil, mechanical and structural engineers to get the job done. In addition to being able to control many tons of weight and measure the deflection of a steel beam, students in Sherman’s lab are expected to get their hands dirty. If they get an incomplete part from the shop, it’s the students that weld it and complete the assembly.

“Having a team that is willing to work together and gain additional experience outside of what they're working on I think is extremely valuable for the students, and it proved to be extremely valuable for me,” said Sherman, who draws inspiration from an extremely collaborative team during his Ph.D. at Purdue University. “The students are can just sit down and have a quick and dirty conversation drawing stuff out on the white board, with no need to pull in the advisor.”

Just as doctors and scientists try to extend the length of the human lifespan, Sherman tries to extend the lives of the bridges we travel over every day by diagnosing and treating what ails them. The coming years are sure to see groundbreaking advances in preserving iconic aging bridges, as well as developing novel ways to build new ones.